Blog

Category: Marketing

What is Electronics Manufacturing Services(ESM)?

Firms that create, produce, test, distribute, and offer return/repair services for electronic components and assemblies for original equipment manufacturers are known as electronics manufacturing services (EMS) companies.

In contrast to other nations like the United States, where maintenance costs are higher, most consumer electronics are produced in China where materials are more readily available and production is faster and cheaper. Cities like Shenzhen and Penang have developed into significant industrial hubs for the sector, drawing several massive consumer electronics businesses like Apple.

History of ESM

After Solectron was founded in the late 1970s, the EMS sector took off. At that time, internal assembly handled the majority of electronics manufacturing for large product runs. The new ESM model provided flexibility and helped small businesses with short production runs with their human resource needs. The EMS industry's business strategy focuses on providing value-added services, such as warranty and repair, as well as large-scale economies of scale in production, resource pooling and the sourcing of raw materials. This relieves the client of having to produce and keep massive product stockpiles. As a result, they can react to unexpected increases in demand more rapidly and effectively.

Electronics may now be assembled quickly thanks to the invention of surface mount technology (SMT) on printed circuit boards (PCBs). OEMs quickly set up SMT lines in the early 1990s. As OEMs cancelled contracts or frequently switched suppliers, EMS players like SCI and Avex struggled to stay in business. By the middle of the 1990s, OEMs started to outsource printed circuit board assembly (PCBA) on a wide scale as the advantages of the EMS concept became clear. Many OEMs sold their assembly facilities to EMSs in the late 1990s and early 2000s as they fiercely competed for market share. As cash-rich EMS enterprises soon acquired both existing factories and smaller EMS firms, a wave of consolidation resulted.

Key ESM Services that Enhance the Value Proposition of Your Products

Electronic manufacturing services companies, or EMS, design, manufacture, test, distribute and provide return/repair services for electronic components and assemblies for original equipment manufacturers (OEMs). They serve a wide range of industries, manufacturing products for medical, consumer electronics, defense, aerospace, energy, automotive, connected objects and more. For a taste of EMS services in action, find out how EMS contract manufacturing is making medium and large enterprises competitive.

Services vary by company, but your ideal EMS provider will offer high-quality design and development services in addition to product manufacturing. Look for some of the following that can help you market your product more effectively:

- Research and Development (R&D): This includes electronic innovations and co-specification R&D projects.

- Co-design: This includes collaborative design and comprehensive product development services.

- Prototyping: Your EMS provider can help with functional mockups and prototype manufacturing.

- Manufacturing. This includes EMS supply chain solutions, lean management, and systems integration (also known as Box Build). These include:

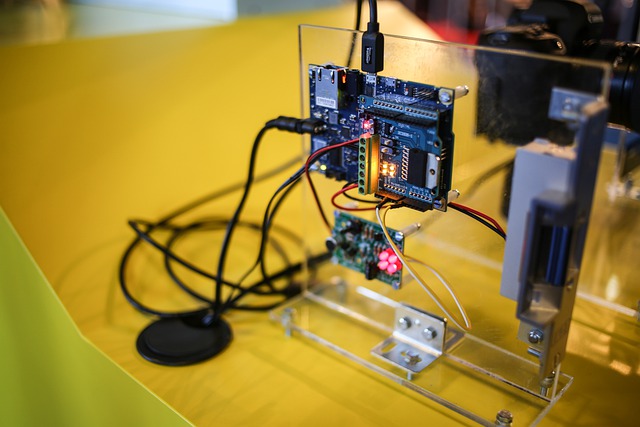

- Printed Circuit Board Assembly (PCBA): PCBA production involves soldering components such as integrated circuits, transistors, and resistors onto a bare board to facilitate power and signal routing between physical devices.